Forging Press Hot Forging Hydraulic Press Machine 1000T

Basic Info

Model No.: Yz14

Product Description

Our company produces three beam four column 800T free forging hydraulic press, 1250T free forging hydraulic press, 1600T free forging hydraulic press, 2000T free forging hydraulic press, 2500T free forging hydraulic press, 3150T free forging hydraulic press, 4000T free forging hydraulic press, 5000T free forging hydraulic press, 6000T free forging Hydraulic Press. Free forging presses are mainly used in various processes for free forging of metal materials, such as: upsetting, punching, reaming, shifting, rough turning, cutting, bending, and lengthening.

Features and advantages of large hot forging hydraulic press:

The hydraulic system has multi-level overload protection, oil temperature alarm, oil level alarm protection and other automatic protection devices. The electrical system adopts mature PLC control to ensure the safety of equipment and operators. The working cylinders are pressed by the large-flow liquid filling valve and the auxiliary fuel tank at the same time, which can realize the oil returning during fast oil filling, oil replenishing and lifting, effectively saving the forging auxiliary time and improving the forging efficiency. The equipment is equipped with a reliable cooling circulation system, which can stably control the temperature rise and ensure the safe and reliable operation of the system.

Hot extrusion forging press is widely used in the production of pipes and profiles of non-ferrous metals such as aluminum and copper, and belongs to the metallurgical industry. Hot extrusion of steel is used to produce special pipes and profiles, as well as carbon steel and alloy steel parts that are difficult to form with cold or hot extrusion, solid and core (through holes or through holes), such as A rod with a large head, a barrel, a container, and the like. The cold extrusion forging press was originally only used to produce pipes, profiles, lead pipes, zinc, tin, aluminum, copper, etc., as well as toothpaste hoses (lead of lead tin), dry battery shells (zinc), cartridges (copper), etc. . The cold extrusion operation is simple and suitable for small parts produced in large quantities.

A hydraulic press is a machine that uses liquid as a working medium to transfer energy to achieve various processes. In addition to forging forming, hydraulic presses can also be used for correction, press fitting, packing, briquetting and pressing. The hydraulic press includes a hydraulic press and a hydraulic press. A water-based liquid is used as a working medium, which is called a hydraulic press, and an oil as a working medium is called a hydraulic press. The specifications of hydraulic presses are generally expressed in terms of nominal working force (kilograms) or nominal tonnage (tons). The hydraulic press for forging is mostly a hydraulic press with a high tonnage.

Features

1.Hydraulic machine that used the hydrostatic pressure to process metal, plastic, rubber, wood, powder and other products .

2. It is commonly used in the pressing process and press forming process, such as: forging, stamping, cold extrusion, straightening, bending, flanging, sheet metal deep drawing, powder metallurgy, press-fit etc.

3.Significant technical and economic advantages in reducing weight, reducing the number of parts and the number of molds, improve the stiffness and strength, reduce production costs, etc.

SPECS

| Model ( four-column type) | unit | Yz14-800T | Yz14-1000T | Yz14-1600T | Yz14-2000T | Yz14-2500T | Yz14-3150T |

| Nominal force | KN | 8000 | 10000 | 16000 | 20000 | 25000 | 31500 |

| Max.Liquid working pressure | MPA | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 |

| Pressure classification | KN | 8 | 10 | 10 | 10 | 10 | 10 |

| Max.open height | MM | 2500 | 2600 | 2800 | 3000 | 3000 | 3500 |

| Return force | KN | 1000 | 1600 | 2000 | 2600 | 3200 | 3600 |

| Slider stroke | MM | 1200 | 1400 | 1600 | 1800 | 2000 | 2100 |

| Center distance of column | MM | 2200*1100 | 2400*1100 | 2800*1200 | 3000*1600 | 3300*1600 | 3400*1600 |

| Dia of column | MM | 260 | 280 | 360 | 400 | 450 | 470 |

| Moving table size (L-R) | MM | 1500 | 1800 | 1800 | 1900 | 2000 | 2000 |

| Moving table size (F-B) | MM | 2800 | 2800 | 3600 | 4500 | 5000 | 6000 |

| Moving table size (H) | MM | 2200 | 2500 | 2500 | 2500 | 3000 | 3500 |

| Moving table stroke | MM | 2*1000 | 2*1000 | 2*1500 | 2*1600 | 2*1600 | 2*2000 |

| Moving table procedural place | MM | 3 | 3 | 3 | 3 | 3 | 3 |

| Foring eccentricity | MM | 100*60 | 100*60 | 140*70 | 150*100 | 150*100 | 200*120 |

| Slider down speed | MM/S | 250 | 250 | 250 | 250 | 250 | 250 |

| Slider pressing speed | MM/S | 70 | 144/70 | 103/50 | 160/105/50 | 110/68 | 180/10/45 |

| Slider return speed | MM/S | 250 | 250 | 250 | 250 | 250 | 250 |

| Speed of moving table | MM/S | 200 | 200 | 200 | 200 | 200 | 200 |

| Times of quick-forging | ONCE/TIMES | 50-60 | 50-60 | 40-50 | 40-50 | 40-50 | 10-50 |

| Main motor power | KW | 660 | 770 | 880 | 1210 | 1760 | 2200 |

Workshop

Packaging and delivery

Contact info

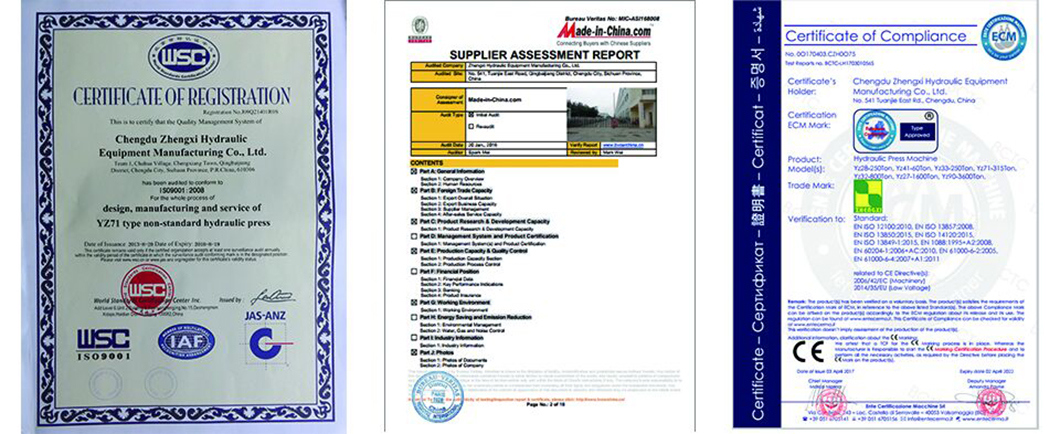

Certificate

After-sale

1.Personnel training

Free training for about one week.

2. After-sale service

One year warranty.During warranty period,free maintenance service can be provided.(except man-made faults or damages arising from irresistible natural factors)

3.Installation

Customers need to pay the commission to our proffessional engineer, and travel expense is on foreign customer.(Including round ticket and accommodation cost)

Our company is an ISO 9001 certified Company, and as an approved supplier for the automotive sector, has also received the CE certificates.This demonstrates that the Quality Assurance System has been fully introduced and adopted, in the interests of providing absolute reliability in our products and careful attention to our customers.

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as 1-16000Tons Hydraulic Press,SMC/BMC/GMT/DMC/LFT/GRP/FRP Press,Hydraulic Deep Drawing Press,Hydraulic Forging Press,Metalworking/Stamping Press.

3: Where is our factory located? How can I visit there?

A : Our factory is located in Jiaomei City ,Fujian Province,China. You are warmly welcomed to visit us.

4: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

5: How about your delivery time?

A: Generally 90 days. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

6: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

7: How do you make our business long-term and good relationship?

A: 1.We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Product Categories : Customization Hydraulic Press > Forging Hydraulic Press